Best Thing to Happen To Cannabis & How Hashish is Saving the Cannabis World

- HASHWRITER

- Aug 28, 2021

- 7 min read

Sometimes you just have to come out and say it like it is: Solventless hash making is the best thing to happen to cannabis in my lifetime. Yes, that's right. Not medicinal cannabis in California, or state legalization in Colorado and Oregon, and certainly not the domino effect of unprepared follower states scrambling to enact self-serving legislation. Not this legal incompetency and manipulation of law and order that has suddenly subsided into a strong-armed licensing power-play and tax-grab called "legalization". The same people profiting from incarceration want to keep their hands on a slice of the pie. Certainly, I won't fall for the idea that cannabis is legal while men and women not only remain in prison for cannabis, but continue to be arrested and prosecuted for it. There's nothing legal about my cannabis felonies.

Natural Resistance

I knew the big guys were dug in for a good stay beyond their time, despite solventless revelations. I may have underestimated the dedication however, to these less effective means. I thought more had moved on, but a few recent quips and odd comments led me to reevaluate the chemical extract industry. Only those financially tied to butane extractions will even make the effort to argue against BHO's abysmal quality, but these lies have led to false arguments and illogical replies. You see, the problem is we do everything backwards thanks to the hyper-consumerism of surveillance capitalism with a side of Prohibition.

Backwards Evolution of BHO

Had quality products been the ideal, we would have come across solventless hash and rosin a long, long time ago. I fight mentally to argue that the cannabis quality itself is what was required for solventless refinement to become possible and that without the advances and interest that Butane Hash allowed, the cannabis quality wouldn't have progressed fast enough for solventless methods. Regardless, no one took a quality cannabis plant and said how do I best refine this... Instead they took a heaping mound of trim, trash, larf, leaf, and scrap and said, "How do we profit from all this trash?" Another detrimental aspect of Prohibition, preventing anyone from risking the research and development necessary. Instead, flowers were gold and we were looking for an effective means to refine the trash.

In A Normal World

A normal world would have used cannabis rather than it's trim to develop a finer product. Solventless measures have been around forever and part of the solventless system did exist long before BHO, but the final steps of modern solventless only came about in the last few years. Had grade A cannabis been used in prior bubble-hash, it probably would have risen to fame long before chemical industries decided to "lend a hand." In this idea of a normal world, it would be common knowledge that only the best comes from ice and water washes. It would be common sense to say the usage of chemicals to refine anything in cannabis is due to a lower quality of cannabis and as a last resort. If water works, why use chemicals?

Quality Yields Solventless

We know that the absolute finest cannabis on earth yields well in ice water hash and that only pristine batches of the best cannabis go toward solventless refinement. There's never been a flower that was too good for ice water hash but there's certainly a ton of flowers out there that could never dream of being refined with only ice and water. While you can put quality cannabis through BHO refinement, why would you? If a fundamentally superior style of product can be obtained in ice and water, who on Earth would want their cannabis soaked and dissolved in Butane instead?

Let's Compare:

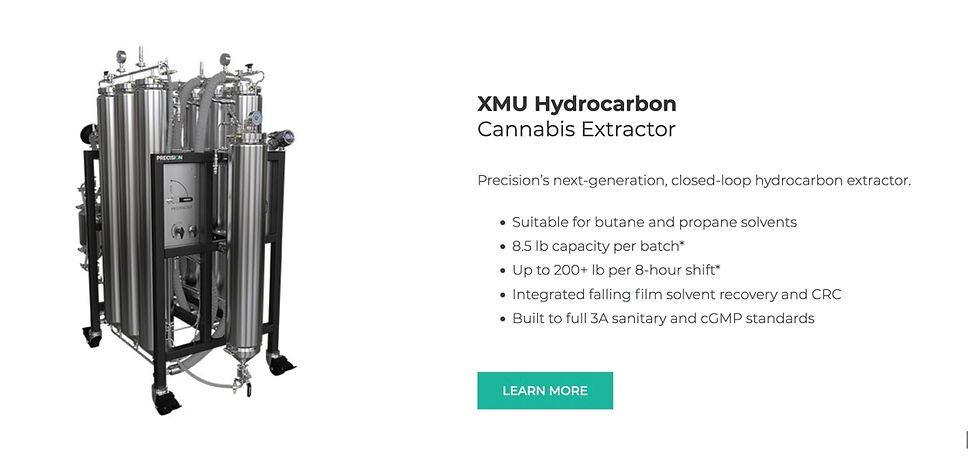

Do you want your cannabis to be stuffed into these pipes and blasted with propane, butane, or ethanol? No thank you. We let scientists pack cannabis into a steel column or pipe attached to a closed loop system, like a giant chemistry set, pumping solvent gasses through the weed, in effect dissolving cannabis trichomes into the solvent. This chemical stew of liquid butane and whatever terpenes and cannabinoids remain is disgusting. We used to allow the butane to simply evaporate, but now use ovens to help purge the remaining butane and call whatever remains, "a product". On the other hand, I'll take my cannabis product made by hand in ice and water that comes from something more like this...

Wash and drain, drain and strain, and give me water hash! It's almost as simple as that. In the long term, understandings will eventually balance out. These strange early days of backward dealings and legally prohibited exploration have slowly come to a close, as a modern understanding of cannabis and the methods to best refine it slowly spread. Ten or twenty years from now BHO will be put into perspective and held alongside distillate for bargain priced products that everyone knows are made from trim. The backward evolution of extracts caused by Prohibition will subside and a more logical understanding will evolve.

Solventless Genetics to Wash

While solventless appeared to be extremely difficult and limited to a very distinct set of genetics, these were some of the earliest claims about solventless hash. An updated understanding of solventless-appropriate genetics has found that the proper phenotype will wash. This means it is up to the grower to pheno-hunt for the right version of a genetic if they want it to "wash". A genetic that will "wash" is hash slang meaning it will yield a fair solventless product. Those that "won't wash," simply haven't searched long or hard enough for the right phenotype of that particular cultivar. While some cultivars like GMO, Papaya, or Wedding Cake seem meant for solventless methods, more and more genetics are found and bred specifically for ice water hash with each passing day.

Cannabis Is Made For Hash

Being cautious not to over-simplify matters too much, it only takes half a day of watching a serious ice water hash operation to think to yourself, "this is too easy! Why on Earth haven't they been doing it like this all along!?" I could not believe the amount of high quality melt being washed from massive amounts of fresh-frozen cannabis. I'm talking sheet tray, after sheet tray, after sheet tray overflowing with sandy trichomes that are simply spooned off mesh screens. Fifteen minutes of hand stirring two side by side 65 gallon pots of ice, weed, and water is all it took to then filter the wash water with just two or three screens. With the wash-basket lined in a 220 micron screen, the next rinse or two is dialed in to yield a ton of trichomes. The process has been dialed in to yield nearly all of the plant's trichomes with just two or maybe three pours and rinses through various micron screens. I walked away thinking cannabis was made for this. Seriously. Cannabis is made for ice water hash.

Back to BHO

My interest and attention to the latest chemical solvent extraction procedures was one of general disregard. I didn't study chemistry and that is who was needed to implement and conduct solvent extractions in bomb-proof (f1a1-or-whatever-the-legal-code-is approved) rooms. Despite originating in the back-yard, (like all good things in cannabis) a few blown-up condos in Colorado was what it took to make solvent extraction a highly regulated practice, requiring chemists to perform the extractions safely.

Replaced By Nerds

Closed-loop systems were developed for the safe extraction with solvents, costing extractors a small fortune, (hence being "dug-in"). I want to know how my products are made maybe more than anyone else, but once you get past the general premise of packing cannabis into a metal tube and "blasting" it with chemical solvents, the rest is pretty much up to a scientist to understand. The industry quickly moved into the hands of trained professionals from other technical or scientific fields. Those responsible for extracting the cannabis and infusing our products had moved further and further away from the heart of the community, meanwhile putting up theoretical walls that made growing and extracting today seem impractical if not impossible at home. Non-smokers in white lab coats had taken over, replacing those who worked, sacrificed, and endured incarceration for the love of the plant.

Our Savior!

Solventless hash slammed the door on chemical extraction, opening the back door for the heart of the community to take the reigns once more. I heard the message early on from people I won't mention and @Pez_bros, and I think almost everyone in the community had a "hair-dryer awakening." Realizing we could make our own extracts again that would melt was so important. And while this was exactly what the industry needed, it took some time to spread. Solventless hash empowered cannabis consumers, growers, and hash makers, placing the ball back in our court. Just when I thought all the real ones, the people who risked incarceration, people who were incarcerated, and everyone who sacrificed for the plant appeared to be pushed out of the industry, in swooped the solventless method to make things right again in the world of weed.

A New Quality

A new quality of cannabis, something the chemical engineers couldn't care less about was required for ice and water refinement. Fresh-frozen or the use of frozen material was the final push needed for solventless products to eliminate BHO and chemical extraction from my diet completely. Once you cross over and realize what was missing from BHO it's impossible to switch back. My years-old hacking cough subsided within days and the whole experience of consuming concentrates evolved. The days of preparing for harsh hits of sauce and diamonds ended and a new experience of tasting cannabis like never before began.

Subscribe for updates and a monthly Hash-letter!

#hashwriter #hashisacrime #hash #hashrosin #hashrosinbadder #hashrosinsauce #rosinsauce #rosinbadder #coldcure #jartech #cannabis #concentrates #cannabisconcentrates #hream #antisolventsolventlessclub #assc #humboldt #humboldtcannabis #sungrown #california #calibud #calicannabis #hashhash #tag